Description

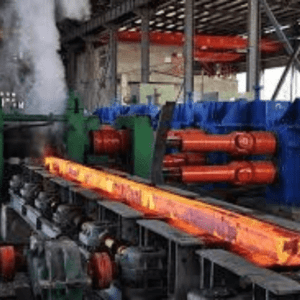

Disposable boards used to form a inner lining for

continuous casting tundishes.

• Avoids the lengthy preheating process & Helps in

significant energy saving.

• Reduces consumption of refractory in tundishes &

Improves quality of steel by providing fresh ISOLIN

lining every time the Tundish board is changed.

• Easy deskulling of Tundish boards at completion of

casting, Improves turn around time significantly and

in turn improves productivity.

Advantages Of Using Tundish Boards

• REDUCED REFRACTORY CONSUMPTION-Minimises

the need to patch and repair of Tundish boards

refractory lining thus ISOLIN system reduce refractory

consumption.

• CONSISTENT METAL TEMPERATURE-Insulating

properties of the Tundish system results in consistent

temperature of the liquid steel.

• EASY DUMPING-After casting a disposable soft

residue left by Tundish boards helps in easy

dumping on turnover station. Hence use of oxygen

lance or pneumatic hammers is eliminated.

• HIGH YIELDS-TUNDISH system minimizes skull

formation thus improves the yield of cast steel.

• BETTER ENVIROMENT-Lower Tundish shell

temperatures help to have cooler surrounding for

the operation.

Reviews

There are no reviews yet.